As noted on the website:

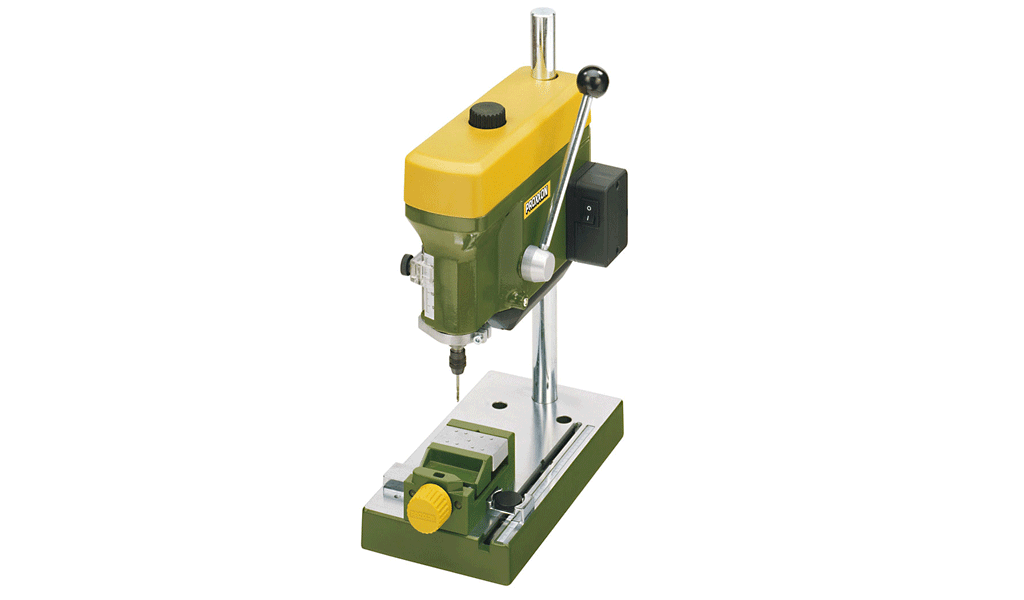

The power transmission by 3-step aluminum pulleys and flat belt provides 3 spindle speeds of 1,800, 4,700 and 8,500rpm allowing triple torque at lower speeds. The chrome feed lever has a practical adjustable drilling depth gauge.

The spindle is essentially free of play as a result of the three high quality ball bearing assemblies. It is recessed for the insertion of MICROMOT steel collets, but also threaded for attaching drill chucks with 3/8" thread. The spindle has an extremely high rotational accuracy and a 1 3/16" (30mm) feed. The quill diameter is 1 1/4" (32mm) with return spring, the throat depth (column to drill spindle) is 5 1/2" (140mm). The unit provides quick coarse height adjustment of the headstock via clamp lever. The max. height (worktable surface to spindle end) is 5 1/2" 140mm).

I find the Bench Drill Press is quite a compact unit sized at 11" tall with a based of 8 1/2" x 4 3/4" making it easy to fit on any work table. The motor is housed in the die-cast machine head and runs very quiet so even drilling late at night or early in the morning does not present a noise issue.

You can quickly change the height adjustment with the attached clamp lever.

I have used the Bench Drill Press for an assortment of projects. Some of those projects are plain unfinished wood items and some of those projects are completed projects. I get the same results with no touch up needed on my completed projects.

Here are some of the projects which I've created using the Hot Wire Cutter. Click on the links for the complete project details.

Thanks for stopping by.

Steph

No comments:

Post a Comment